Here, I've pinned the jacket shut to simulate buttons. Everything is done except for the sleeve hems. Peter thought I might want to put seam binding along the bottoms of the sleeves and I plan to pin some there to see what it looks like. He may be right. You might notice that I have put a row of pins down the fronts, to hold the fabric up and keep it from buckling at the bottom edge. I may take a few loose stitches in the shoulders to prevent this from happening in the finished jacket.

The skirt is complete. I decided to cut a few pieces of bias from the satin and finish the skirt hem in it. I sewed the satin on by machine to the raw edge of the hem and then I folded the other raw edge under and hand sewed the hem to the skirt. And no one will ever see this.

Back to finishing the inside of the hem on the jacket. Before I could sew down the lining to the hem, I wanted to finish that tiny bit of raw fabric at the bottom edge of the facing. The Threads magazine suggests putting a bit of bias tape on it and in this photo, I have pinned the tape to the edge. I sewed it to the edge by machine before folding it over to encase the raw edge of the facing. By machine sewing, I also was able to catch the end of the piping cord in the stitching, thus anchoring it even more than I had already.

Then I folded the tape around the edge of the facing and tucked the end under and sewed it down by hand. You might want to make this photo larger to see the detail. For someone who is picky about finishing the insides of her garments, even this may be a bit much for me for future jackets. The piping is nice but I wonder if it's worth it, especially with the fuss at the bottom because f the fold in the lining for ease. If I do this again, I may have to eliminate that fold. But I like the bit of bias over the raw edge.

Here is the jacket on Rose, inside-out. The lining hem is pinned up to the jacket hem. I suppose it looks a little more relaxed, now that I've sewed it but I'm not convinced the piping is worth the trouble.

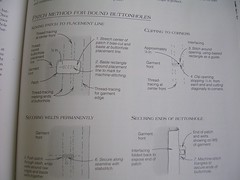

I think the jacket does need more of the piping fabric as an accent on the exterior. That's why I'm going to test it around the bottom edge of the sleeves when I hem them, and that's why I'm going to use it on the buttonholes. I can't use my automatic buttonholer anyway, because of the thick piping at the front edge of the jacket. So I'm going to do some machine zigzaging to make the fabric sturdy and then do a bound buttonhole with the floral fabric. And then I am going to make fairly large covered buttons using the floral fabric to cover them! I can't imagine this jacket with any other buttons - plastic, pink, gold or whatever. I think they have to be covered in the floral. So that's next, after I make the trek to Fabricland for the button forms.